The iTero digital scanner allows dentists & their patients to quickly & clearly view images right in the treatment room. This imaging allows the dentist to clearly explain needed treatment while showing you exactly what is happening with your smile. The high-definition rendering can show teeth in fine detail so even small chips or cavities can be clearly viewed. The iTero does not produce any x-ray radiation, and utilizes Near Infrared technology to aid in the detection of cavities.

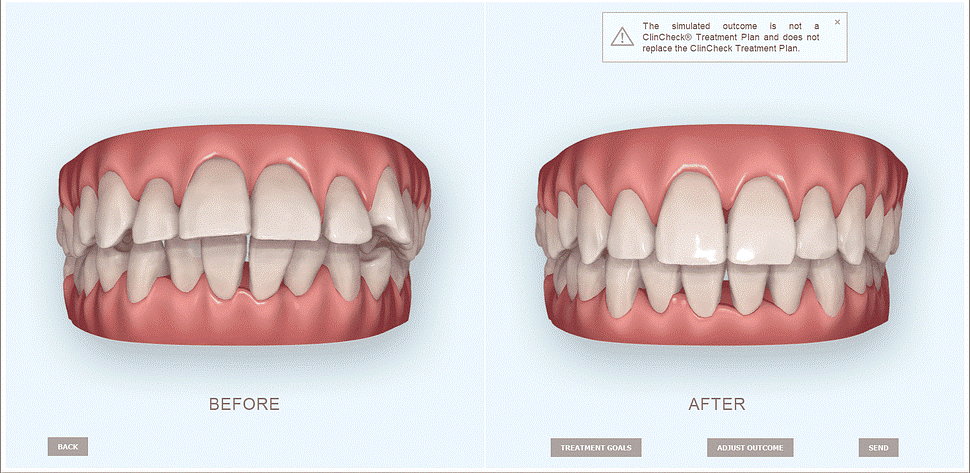

This type of scanning is great for raising patient awareness of their health & needed treatment and it can also help with the treatment itself. Using 3-D images from the scanner, dentists can create digital impressions & show estimations of results. For example, iTero scanners can simulate what Invisalign clear aligners can do for you to give you a realistic expectation that helps you make an informed decision.

Once you have begun treatment, you can view the progress of longer treatments through time-lapse & other effects.

CEREC is an incredible dental technology that utilizes digital imaging to deliver same-day dentistry to our patients We use the CEREC Primescan to fabricate indirect restorations like crowns, onlays, and veneers in a single day. CEREC is a proven technology that has been used successfully by dentists for decades that can produce the highest quality dentistry in a convenient manner. We can use all-ceramic, tooth-colored materials and complete treatment within the span of a few hours.

By taking a digital impression, we can avoid taking traditional “goopy” impressions that are sent to the laboratory and take weeks to be returned. The digital scan takes a matter of minutes to complete and completely avoids temporaries.

The CEREC 3D software converts the series of image into a three-dimensional model, which can be used by the dentist to design and customize the dental restoration. We select a ceramic block that matches the tooth shade and insert it into the milling machine. We have a variety of lithium disilicate and zirconia blocks to choose from. Once milled, the restoration is then placed into a ceramic furnace, fired and glazed, and transformed into its final state. We then can try in the restoration and cement it permanently, all without the use of temporaries or impression materials.